|

|

|

| You are here: Home> Products > Gate |

|

|

|

|

|

| Product Name:GB bellows flange globe valve |

| Product Classification:Globe valve |

| Product Introduction: |

WJ41H, WJ41W type PN16 ~ PN40 bellows valve for working pressure 1.6 ~ 4.0MPa, operating temperature -29 ~ 350 ℃ oil, chemical, pharmaceutical, fertilizer, power industry and other working conditions, and is broken or adjust the pipe connected to the media. |

|

| Description |

Parameters |

Size Chart |

Application |

|

, reasonable structure, reliable sealing

2, the sealing surface of Co-based alloy hardfacing, wear, corrosion, anti-friction performance and long service life

3, stem quenched and surface nitriding, has good corrosion and anti-friction properties

4, parts materials and flanges, welding end size according to actual conditions or reasonable matching user requirements to meet the requirements of various engineering

5, the valve needs to be done according to order of cut-off and modulating

|

|

|

part name |

body |

bonnet |

stem |

disc |

sealing surface |

Filler |

|

WCB |

WCB |

WCB |

13Cr |

2Cr13 |

2Cr13 |

GRAPHITE |

|

STL |

|

304 |

CF8 |

CF8 |

304 |

304 |

304 |

GRAPHITE |

|

STL |

PTFE |

|

316 |

CF8M |

CF8M |

316 |

316 |

316 |

GRAPHITE |

|

STL |

PTFE |

|

304L |

CF3 |

CF3 |

316 |

304L |

304L |

GRAPHITE |

|

STL |

PTFE |

|

316L |

CF3M |

CF3M |

316 |

316L |

316L |

GRAPHITE |

|

STL |

PTFE |

|

|

External and connection dimensions:

|

PN |

DN |

L |

L1 |

D |

D1 |

D2 |

B |

f |

F |

D6 |

N-ф |

△H(

STRODE) |

|

1.6 |

15 |

130 |

80 |

95 |

65 |

45 |

14 |

2 |

- |

- |

4-14 |

6 |

|

20 |

150 |

90 |

105 |

75 |

55 |

14 |

2 |

- |

- |

4-14 |

6 |

|

25 |

160 |

110 |

115 |

85 |

65 |

14 |

2 |

- |

- |

4-14 |

8 |

|

32 |

180 |

127 |

135 |

100 |

78 |

16 |

2 |

- |

- |

4-18 |

8 |

|

40 |

200 |

156 |

145 |

110 |

85 |

16 |

3 |

- |

- |

4-18 |

13 |

|

50 |

230 |

170 |

160 |

125 |

100 |

16 |

3 |

- |

- |

4-18 |

13 |

|

65 |

290 |

- |

180 |

145 |

120 |

18 |

3 |

- |

- |

4-18 |

16 |

|

80 |

310 |

- |

195 |

160 |

135 |

20 |

3 |

- |

- |

8-18 |

20 |

|

100 |

350 |

- |

215 |

180 |

155 |

20 |

3 |

- |

- |

8-18 |

25 |

|

125 |

400 |

- |

245 |

210 |

185 |

22 |

3 |

- |

- |

8-18 |

32 |

|

150 |

480 |

- |

280 |

240 |

210 |

24 |

3 |

- |

- |

8-23 |

40 |

|

200 |

600 |

- |

335 |

295 |

265 |

26 |

3 |

- |

- |

12-23 |

50 |

|

2.5 |

15 |

130 |

80 |

95 |

65 |

45 |

16 |

2 |

- |

- |

4-14 |

6 |

|

20 |

150 |

90 |

105 |

75 |

55 |

16 |

2 |

- |

- |

4-14 |

6 |

|

25 |

160 |

110 |

115 |

85 |

65 |

16 |

2 |

- |

- |

4-14 |

8 |

|

32 |

180 |

127 |

135 |

100 |

78 |

18 |

2 |

- |

- |

4-18 |

8 |

|

40 |

200 |

156 |

145 |

110 |

85 |

18 |

3 |

- |

- |

4-18 |

13 |

|

50 |

230 |

170 |

160 |

125 |

100 |

20 |

3 |

- |

- |

4-18 |

13 |

|

65 |

290 |

- |

180 |

145 |

120 |

22 |

3 |

- |

- |

8-18 |

16 |

|

80 |

310 |

- |

195 |

160 |

135 |

24 |

3 |

- |

- |

8-18 |

20 |

|

100 |

350 |

- |

230 |

190 |

160 |

28 |

3 |

- |

- |

8-23 |

25 |

|

125 |

400 |

- |

270 |

220 |

188 |

30 |

3 |

- |

- |

8-25 |

32 |

|

150 |

480 |

- |

300 |

250 |

218 |

34 |

3 |

- |

- |

8-25 |

40 |

|

200 |

600 |

- |

360 |

310 |

278 |

16 |

3 |

- |

- |

12-25 |

50 |

|

4.0 |

15 |

130 |

80 |

95 |

65 |

45 |

16 |

2 |

4 |

40 |

4-14 |

6 |

|

20 |

150 |

90 |

105 |

75 |

55 |

16 |

2 |

4 |

51 |

4-14 |

6 |

|

25 |

160 |

110 |

115 |

85 |

65 |

16 |

2 |

4 |

58 |

4-14 |

8 |

|

32 |

180 |

127 |

135 |

100 |

78 |

18 |

2 |

4 |

66 |

4-18 |

8 |

|

40 |

200 |

156 |

145 |

110 |

85 |

18 |

3 |

4 |

76 |

4-18 |

13 |

|

50 |

230 |

170 |

160 |

125 |

100 |

20 |

3 |

4 |

88 |

4-18 |

13 |

|

65 |

290 |

- |

180 |

145 |

120 |

22 |

3 |

4 |

110 |

8-18 |

16 |

|

80 |

310 |

- |

195 |

160 |

135 |

22 |

3 |

4 |

121 |

8-18 |

20 |

|

100 |

350 |

- |

230 |

190 |

160 |

24 |

3 |

4.5 |

150 |

8-23 |

25 |

|

125 |

400 |

- |

270 |

220 |

188 |

28 |

3 |

4.5 |

176 |

8-25 |

32 |

|

150 |

480 |

- |

300 |

250 |

218 |

30 |

3 |

4.5 |

204 |

8-25 |

40 |

|

|

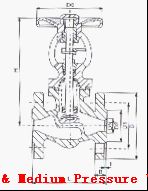

产品外形及结构尺寸示意图

|

1 hand wheel, lever operated valves can be installed in any position in the pipeline.

2 hand wheels, handles and Wei moving body does not allow for lifting purposes.

3 medium as shown in the flow direction of the arrow should be consistent with the body.

|

|