|

|

|

| You are here: Home> Products > Gate |

|

|

|

|

|

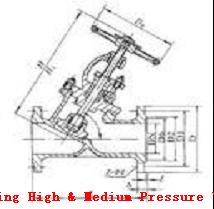

| Product Name:Y-forged steel globe valve |

| Product Classification:Globe valve |

| Product Introduction: |

The process of opening and closing the friction between the sealing surface is small, more durable, opening height is not easy to manufacture, easy maintenance, not only for low-voltage, and for high pressure. |

|

| Description |

Parameters |

Size Chart |

Application |

|

The following structure

1.Full bore or reduced bore

2.Ball-type check valve lift and

3.Built-in spring-demand

4.Removable solid valve

5.Self-centering plate pressure sleeve

6.Integral sealing seat on the

7.The next shot stent (OS & Y)

8.Bolts, spiral wound gasket sealing bonnet, threaded connection, seal welded bonnet and threaded pressure self-tight valve cover

9.Comply with ASME B16.11 Socket end

10.Screwed Ends (NPT) comply with ANSI / ASME B1.20.1

11.Valve can be transformed into needle, throttle type, ball type, non-return-type

|

|

Y-Globe Valve 800Lb-2500Lb forged steel material selection table

|

NO. |

Part Name |

CS to ASTM |

AS to ASTM |

SS to ASTM |

|

Type A105N |

Type F22 |

Type F304(L) |

Type F316(L) |

|

1 |

Valve body |

A105N |

A182 F22 |

A182 F304(L) |

A182 F316(L) |

|

2 |

Disc |

A276 420 |

A276 304 |

A276 304(L) |

A276 316(L) |

|

3 |

Valve stem |

A182 F6a |

A182 F304 |

A182 F304(L) |

A182 F316(L) |

|

4 |

Gasket |

316clip flexible graphite |

316clip PTFE |

|

5 |

Valve cover |

A105N |

A182 F304 |

A182 F304(L) |

A182 F316(L) |

|

6 |

Valve cover bolt |

A193 B7 |

A193 B16 |

A193 B8 |

A193 B8M |

|

7 |

Cylindrical pin |

A276 420 |

A276 304 |

|

8 |

Packing gland |

A276 410 |

A182 F304(L) |

A182 F316(L) |

|

9 |

Live bolt |

A193 B7 |

A193 B16 |

A193 B8 |

A193 B8M |

|

10 |

Filler plate |

A105N |

A182 F304 |

|

11 |

Nut |

A194 2H |

A194 4 |

A194 8 |

A194 8M |

|

12 |

Stem nut |

A276 420 |

|

13 |

nur |

A194 2H |

A194 4 |

A194 8 |

A194 8M |

|

14 |

Nameplate |

SS |

|

15 |

Handwheel |

A197 |

|

16 |

Filler |

Flexible graphite |

PTFE |

|

Medium |

Water,steam,oil,ect |

Water,steam,oil,ect |

Nitric acid,acetic acid,etc. |

|

Temperature

|

-29°C~425°C |

-29°C~550°C |

-29°C~200°C |

|

产品外形及结构尺寸示意图

|

| Valve maintenance, also pay attention to the first and the transmission of electric water problems. Infiltration of rainwater, especially during the rainy season. First, the transmission or drive shaft cover rust, and second, the winter freeze. Caused by electric valve operation torque is too large, no-load damage to transmission components or super torque motor would jump to protect electric operation can not be achieved. Damage to transmission parts, manual operation can not be. After the action in the ultra-torque protection, also can not switch to manual operation, such as the forced operation, the damage to the internal alloy components.

|

|